gsnake 29-03-2014 21:19

ASDER_K 29-03-2014 21:54

There are wheels with alloy disks, where the hole parameters are 4x98, but on a car you need 4x100. Do you think this is possible?

I have studs on my hub. I read that you can’t do this with bolts, but for some reason it’s better with studs.

Kroilovo leads to Padalov.

greed is one of the most vile vices.

conclusion. sell these discs. corresponding to the size buy.

and don't skimp on condoms. treatment is more expensive.

gallak 29-03-2014 21:57

It will be bad. In the 90s, the former market In the USSR, a ton of new and used 4*100 wheels appeared - many VAZ employees rushed to install them, but an obliquely twisted bolt (in this case, a nut (because studs)) quickly broke the fit of the disk and sometimes the disk broke off at the most inopportune moment...

HARON 29-03-2014 22:04

It is forbidden. On the contrary, no matter what, it’s impossible.

ASDER_K 29-03-2014 22:29

On the contrary, no matter what, it’s impossible.

on the contrary, it didn’t go anywhere either

HARON 29-03-2014 22:34

ASDER_K 29-03-2014 22:43

quote: Originally posted by HARON:

They put it the other way around, but since the vehicle wants it, it doesn’t. I didn’t come up with this, I’ve seen it on the Internet many times.

so not from a great mind. and out of great greed...

at best, cutting will lead to replacing the hub...

Union_Jack 29-03-2014 23:32

someone recently rubbed in that 98 are suitable instead of 100

HARON 30-03-2014 08:45

quote: Originally posted by Union_Jack:

someone recently rubbed in that 98 are suitable instead of 100

Maybe I got it wrong too.

polex 30-03-2014 10:01

quote: sell these discs. corresponding to the size buy.

there's no better way to say it

HARON 30-03-2014 11:54

If bore diameter the one that is needed - I would try it.

gsnake 30-03-2014 12:02

I just assume that these two millimeters will go into tolerances...

HARON 30-03-2014 12:07

They won’t go away, but it should fit. If central diameter If it doesn’t match, then there’s no point in trying it on - screw it on, but it will hit.

Volga sky 30-03-2014 17:48

quote: Originally posted by gsnake:

where are the hole parameters

There are only black holes, and only in space. Everything else is holes.

Kroilovo leads to Padalov.

I already told him this, he doesn’t believe me.

quote: Originally posted by HARON:

but it should fit.

It will fit, but then, when the nut enters the cone, it will begin to bend the stud towards the center of the cone. There are a lot of potholes on the roads...

HARON 30-03-2014 17:54

quote: Originally posted by Volga sky:

It will fit, but then, when the nut enters the cone, it will begin to bend the stud towards the center of the cone. There are a lot of potholes on the roads...

Well, all the studs will bend a little; they all work in tension, not shear. If the landing gear is identical, I would install it, since there are disks.

Comrade Beria 30-03-2014 18:10

Try to bore it in the machine so as not to lose alignment

When unpleasant consequences occur, think about post number 2.

gsnake 30-03-2014 18:23

thanks for the advice. I won't do that.

But then another question - if the wheels fit on the studs, and the central hole is hefty - is that acceptable?

HARON 30-03-2014 18:27

Acceptable, you need to buy or grind an adapter.

gallak 30-03-2014 18:37

quote: If the wheels fit on the studs, and the central hole is hefty, is that acceptable?

This is the situation with most “aftermarket” alloy wheels - because Different automakers have different centering diameters, it is expensive to make wheels only “for Nissan” or “Toyota”, they make them with the largest diameter, and offer adapter rings for smaller ones. These adapters are always available in stores/car service centers that sell discs. If you know the manufacturer of your disc, it is easy to find the corresponding rings. Their cost is 2-3 dollars apiece - cheaper than turning them...

Kir* 31-03-2014 12:48

ASDER_K 31-03-2014 01:28

Bolts are possible. Easy and relaxed. 1 mm on each side is nothing. You need to pull evenly. But how to tighten the disc onto the studs?

muhaha. Don't forget to write a will in advance and buy wheel bearings...

Kir* 31-03-2014 01:43

muha ha or not mu ha ha but 3 years everything is OK

Kir* 31-03-2014 01:44

As for the wheel bearings, that's nonsense.

Ramil 31-03-2014 07:10

Tazovskie to Nexia - this is no longer poverty, this is drug addiction nonsense

Maxim V 31-03-2014 07:29

And these people teach me how to live.... such a thought has never occurred to me - to nail the wheels with a hammer....

Pavel_A 31-03-2014 08:00

There were similar disks. They didn’t fit on the basin, so I sawed all 5 pieces with a grinder and sold them for scrap.

About the centering rings - nonsense. They do not center anything if tapered nuts or bolts are used.

If you don’t want to lose your wheels, don’t even think about installing them.

HARON 31-03-2014 08:09

And so many connoisseurs... And if you didn’t have to tighten the Fiat size, then with the centering rings you have run tens of thousands... Connoisseurs will be even more surprised - these rings also come in plastic. And they’re so scared - the hubs will fall apart, and a will is necessary...

Pavel_A 31-03-2014 08:26

quote: Originally posted by HARON:

And so many experts... And if I didn’t have to tighten the Fiat size, I’ve run tens of thousands with centering rings.

The topic of rings was already discussed here several years ago. There are two types of wheel alignment. By the hub and by bolts/studs. It makes no sense to mix these two alignment methods.

Kir* 31-03-2014 11:55

As I remember now. In '94 or '95, my father bought himself a new Omega and gave me a VW Jetta. So I screwed it on it alloy wheels from TAZ. Until 1998, she rode them safely without any problems. When I bought my wife a pointer with a 4x100 bolt pattern, I remembered that I had a 15 forging with good summer tires from a 8 lying around at my dacha. And I remembered that Jetta felt great with the same problem. I bought good original cone bolts. Screwed it on. This summer will be the 4th that the car will be driven on these wheels.

PS What is the most important thing in a bolted wheel? So that it is well pressed with its inner seating plane to the hub/brake disc.

Makc k-113 31-03-2014 13:15

On a disk with mismatched holes for bolts/studs, you can slowly and sadly get to the place where it will be replaced with a standard one. Driving on such a disk as on a standard one - well, in principle, Kutlhu does not prohibit it. But he doesn’t forbid Russian roulette either - he doesn’t care about the fun of two-legged people.

HARON 31-03-2014 13:19

Okay, I’ll suggest an option - adapter spacers. From any size to any desired, and studs and bolts... Well, the stem will most likely change and the cost is inhumane, but it’s an option?

ASDER_K 31-03-2014 13:31

quote: Originally posted by Kir*:

When we bought my wife a pointer with a 4x100 bolt pattern, I remembered that I had a 15 forging with good summer tires from a 8 lying around at my dacha. And I remembered that Jetta felt great with the same problem. I bought good original cone bolts. Screwed it on. This summer will be the 4th that the car will be driven on these wheels.

you have to be so greedy...

Kir* 31-03-2014 13:31

It's not something to joke about with takeout. Here the load on the bearing is increased. And all the factory suspension settings are down the drain. It’s okay when there’s still a 3-5 mm difference in the offset on the disc itself. But the spacer is at least 15-20 mm.

However, on the Porchik I had spacers at the back of 5 centimeters on each side. And 10 inch wheels. and nothing.

ASDER_K 31-03-2014 13:44

quote: Originally posted by Kir*:

Why should good things go to waste? a set of wheels cost about fifty dollars. Forging with Toyo 888.

This is exactly what I'm talking about...

Kir* 31-03-2014 13:48

quote: Originally posted by ASDER_K:

This is exactly what I'm talking about...

Yes, we are Jews like that

perstkov 31-03-2014 14:13

Of course you can, just buy a tap to correct the thread, and insure your life, it’s a small thing, but your relatives will be pleased

Kir* 31-03-2014 14:20

ASDER_K 31-03-2014 14:24

quote: Originally posted by Kir*:

By the way, if we are talking about wills and insurance: I would be more wary of screwing wheels with a universal 2nd 3rd drill onto the car. So there this knot is weakened

is this like this?

Kir* 31-03-2014 14:36

quote: Originally posted by ASDER_K:

all sorts of crap happens...

is this like this?

ASDER_K 31-03-2014 14:52

The most important question is - nakera one nada?

Kir* 31-03-2014 15:04

quote: Originally posted by ASDER_K:

The most important question is - nakera one nada?

HARON 31-03-2014 15:15

quote: Originally posted by Kir*:Wow! Yes, but this is a handicraft, but there are factory wheels of this kind.

Moreover, if the Japs, at the very least, make them more or less durable, then China is generally tough..

ASDER_K 31-03-2014 15:18

quote: Originally posted by Kir*:

One disk for different machines. Versatility.

why?

HARON 31-03-2014 15:38

quote: Originally posted by ASDER_K:

why?

ASDER_K 31-03-2014 15:46

quote: Originally posted by HARON:

One article instead of three to five.

those. for the convenience of the manufacturer and seller?

why buy such disks for their convenience?

Kir* 31-03-2014 15:48

quote: Originally posted by HARON:Isn't there a piece of iron embedded in luminium?

Well, I didn’t cut such a disc with a grinder. But I highly doubt that there is anything inside. This will further weaken the structure. Although it’s reinforced aluminum as a monolith, there’s a plate inside that’s in no way connected to the aluminum.

HARON 31-03-2014 15:57

I didn’t saw with a grinder either... But judging by the fact that someone is practicing this, the alloy is not homogeneous, there are inserts... However, when buying recyclable materials, there is a separate price list for alloy wheels, they are sold as is.

ASDER_K 31-03-2014 16:07

quote: Originally posted by HARON:

the alloy is not homogeneous, there are inserts...

I have seen broken ones more than once... there were no irregularities in the broken parts.

HARON 31-03-2014 16:13

ASDER_K 31-03-2014 16:14

quote: Originally posted by HARON:

Why then go through the trouble of sawing luminium with a grinder, so that you can then get three kopecks from a metal shop?

I can't know

Kir* 31-03-2014 16:54

quote: Originally posted by HARON:

Why then go through the trouble of sawing luminium with a grinder, so that you can then get three kopecks from a metal shop?

Probably so that people don’t buy them whole and then sell them whole... Or maybe they’re too lazy to remove the rubber during installation.

ASDER_K 31-03-2014 16:56

quote: Originally posted by Kir*:

Or maybe I’m too lazy to remove the rubber during installation.

not lazy, but worth the money...

HARON 31-03-2014 17:08

quote: Originally posted by ASDER_K:

not lazy, but worth the money...

Is it really that expensive? Anyone who has ever cut aluminum with a grinder will not save on tire fitting.

ASDER_K 31-03-2014 17:18

quote: Originally posted by HARON:

Is it really that expensive? Anyone who has ever cut aluminum with a grinder will not save on tire fitting.

As the example of even this topic shows, greed has no limits.

Kir* 31-03-2014 17:28

quote: Originally posted by ASDER_K:

As the example of even this topic shows, greed has no limits.HARON 31-03-2014 22:30

quote: Originally posted by Makc k-113:

How is it not? 4*98 - all VAZs except all-wheel drive. And 4*100 - almost all other cars have 13-14" wheels.Not just vases. I'm sure Fiat also uses 4/98.

Beauty, of course, requires sacrifice, but it’s still not worth going beyond the boundaries of healthy logic. When choosing wheels for a VAZ-2114, you need to be guided not only and not so much by the design of casting or stamping, but also by the dimensions in the first place. Compliance of the factory seating dimensions with the dimensions of the new wheels will guarantee safe operation of the vehicle.

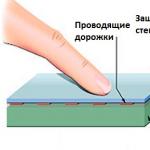

One of the main parameters that you should pay attention to when replacing standard wheels on a VAZ-2114 car is the dimensions, location and diameters of the mounting holes, PCD, pitch circle diameter, or, in simple terms, drilling or bolt pattern.

Bolt pattern on a VAZ-2114 wheel

Bolt pattern - this characteristic is expressed in two numbers and indicates the distance between the centers of the mounting holes and their number.

Drilling for all VAZ cars(except Oka and Niva) - 4x98, four holes whose centers are located at a distance 98 mm apart .

However, this is a simplified designation for the user. The disc manufacturer is required to take into account both the diameter of the holes, their number, the distance between their centers, and the diameter along which the centers of the holes are located. Such a designation would complicate the user’s choice of disks, so knowing drilling in the “number of holes/distance between them” format is considered sufficient.

A few more wheel parameters

The drill bit can be measured using the spare wheel. In all SAMARA drilling 4*98

There are several more parameters that relate to the original VAZ-2114 rims - this is the width of the stock rim 5.0J, disc removal ET45, diameter of the centering hole along the hub - 58,5 .

How to install a 4x100 disk on a VAZ-2114

Most older foreign cars have a 4x100 drill. This makes it possible to diversify the choice of disks almost indefinitely. However, it must be taken into account that easy installation, without modifications, 4x100 wheels on a 4x98 fit will not lead to anything good. The point is that The tolerance in disc manufacturing does not exceed 0.7-1 mm. That is, it is theoretically possible to put on a disk with a 4x100 fit, but this will lead to the fact that only one bolt out of four will fit exactly on the cone. The remaining fasteners simply will not tighten all the way and, as a result, the disk will sit with a distortion that is almost impossible to check by eye.

Disc with bolt pattern 4*100

The disc will not fit with its mating plane to the hub, and this will lead to the fact that it will have a runout.

Systematic runout can not only lead to the fact that the only bolt that is tightened correctly will quickly loosen, but also to instant wear of the wheel bearing, and the remaining bolts will loosen on their own. There is a way out of this situation.

Disc runout leads to rapid wear of the wheel bearing

To install a disc with a 4*100 bolt pattern, you need to either install a spacer or install studs with nuts instead of bolts.

A less reliable option is to install bolts with an offset head. A not entirely correct option is to install studs, for example, from the cylinder head and nuts from Niva, but the studs are not designed for torsional force, so the most reliable option would be. You can make them yourself or buy them ready-made.

But here you need to take into account several nuances:

- The width of the spacer must be at least 20 mm, since only in this case we will ensure proper thread strength.

- In this case, the offset of the disk will increase by the same 20 mm, which must be taken into account when selecting a disk.

- In this case, the disk must be selected with a minimum offset in order to relieve the load and somehow compensate for the difference in offset.

Video about installing spacers to change drilling on a VAZ-2114

Conclusion

Be careful when replacing disks with non-standard ones and remember that the most lethal appearance will never replace security, especially on high speeds. Have a successful and safe journey everyone!

- 4 is the number of bolt holes.

- 98 and 100 are the diameter of the circle in mm on which they are located.

A more popular way to install 4x100 wheels on a VAZ is to use bolts with an eccentric or with an offset center. Sets of such non-standard bolts can be easily found in online stores.

If discs are installed incorrectly on a VAZ with a 4x100 bolt pattern, vibrations may appear at speed, and during sharp braking, death may occur, so before installation, think about safety first!

By the way, do you know what tires and wheels are suitable for the VAZ 2110?

Photo source:- Che-guevaro logbook from Drive2.ru

Key words:

xn--2111-43da1a8c.xn--p1ai

What kind of drilling on a VAZ-2114: photo and video

Beauty, of course, requires sacrifice, but it’s still not worth going beyond the boundaries of healthy logic. When choosing wheels for a VAZ-2114, you need to be guided not only and not so much by the design of casting or stamping, but also by the dimensions in the first place. Compliance of the factory seating dimensions with the dimensions of the new wheels will guarantee safe operation of the vehicle.

What kind of drilling is on the VAZ-2114

One of the main parameters that you should pay attention to when replacing standard wheels on a VAZ-2114 car is the dimensions, location and diameters of the mounting holes, PCD, pitch circle diameter, or, in simple terms, drilling or bolt pattern.

Bolt pattern on a VAZ-2114 wheel

Bolt pattern - this characteristic is expressed in two numbers and indicates the distance between the centers of the mounting holes and their number.

Drilling for all VAZ cars (except Oka and Niva) - 4x98, four holes, the centers of which are located at a distance of 98 mm from each other.

However, this is a simplified designation for the user. The disc manufacturer is required to take into account both the diameter of the holes, their number, the distance between their centers, and the diameter along which the centers of the holes are located. Such a designation would complicate the user’s choice of disks, so knowing drilling in the “number of holes/distance between them” format is considered sufficient.

A few more wheel parameters

The drill bit can be measured using the spare wheel. In all SAMARA drilling 4*98

There are several more parameters that relate to the original VAZ-2114 rims - the width of the stock rim is 5.0J, the offset of the ET45 rim, the diameter of the centering hole at the hub is 58.5.

How to install a 4x100 disk on a VAZ-2114

Most older foreign cars have a 4x100 drill. This makes it possible to diversify the choice of disks almost indefinitely. However, we must take into account that simply installing, without modifications, 4x100 wheels on a 4x98 seat will not lead to anything good. The fact is that the tolerance in the manufacture of the disk does not exceed 0.7-1 mm. That is, it is theoretically possible to put on a disk with a 4x100 fit, but this will lead to the fact that only one bolt out of four will fit exactly on the cone. The remaining fasteners simply will not tighten all the way and, as a result, the disk will sit with a distortion that is almost impossible to check by eye.

Disc with bolt pattern 4*100

The disc will not fit with its mating plane to the hub, and this will lead to the fact that it will have a runout.

Systematic runout can not only lead to the fact that the only correctly tightened bolt will quickly become loose, but also to instant wear of the wheel bearing, and the remaining bolts will loosen on their own. There is a way out of this situation.

Disc runout leads to rapid wear of the wheel bearing

To install a disc with a 4*100 bolt pattern, you need to either install a spacer or install studs with nuts instead of bolts.

A less reliable option is to install bolts with an offset head. A not entirely correct option is to install studs, for example, from the cylinder head and nuts from Niva, but the studs are not designed for torsional force, so the most reliable option would be to install spacers. You can carve them yourself or buy them ready-made.

But here you need to take into account several nuances:

- The width of the spacer must be at least 20 mm, since only in this case we will ensure proper thread strength.

- In this case, the offset of the disk will increase by the same 20 mm, which must be taken into account when selecting a disk.

- In this case, the disc must be selected with a minimum offset in order to remove the load from the hub and somehow compensate for the difference in offset.

Using off-center eccentric bolts

Using off-center eccentric bolts

Install wheel spacers

Install wheel spacers

Installing studs with eccentric nut

Installing studs with eccentric nut Video about installing spacers to change drilling on a VAZ-2114

Conclusion

Be careful when replacing disks with non-standard ones and remember that the most killer appearance can never replace safety, especially at high speeds. Have a successful and safe journey everyone!