Recently they have become very popular portable chargers For mobile phones or else they are called Power Bank . They are sold in many stores, and we can buy them without any problems, but I think many radio amateurs are much more interested make your own portable one charger for your mobile phone. This article will show you a simple scheme charger powered by AA batteries.

Almost all devices that are recharged via a computer’s USB, such as mobile phones, MP3 players, cameras and much more, can be charged using regular 1.5 volt AA batteries; if desired, they can be replaced with rechargeable batteries.

Experimental model of a portable charger with surge protection:

The diagram according to which you need to assemble the charger:

Since the circuit uses discrete components, a surge protection system has been included in case any element fails. How the scheme works will be described below.

The main component of the circuit is chip 7805, which is a 5-volt voltage regulator with a maximum output current of 1.5 amperes. Therefore, this charger will supply a maximum of 1.5 A to charge your mobile.

Let's make a small digression from the topic. I recently came across a problem: I needed to help my relatives from Germany get a visa, the queues at the embassy turned out to be a couple of months ahead, and then I came across the website http://www.visardo.ru/ where the visa was issued in just a week.

The zener diode in the circuit provides output voltage no more than 5.6 volts, and if the output voltage exceeds 5.6 volts, automatically protection will work turning off the power to the 7805 chip.

For reliability, you can install a 2A fuse in front of the microcircuit to be more sure that the charger will turn off when an overvoltage occurs.

The output of 7805 is connected to a female USB from which you will charge your gadget. In this circuit we used four AA batteries of 1.5V and 1.5A.

Well, yes, perhaps this charger will be larger than those sold in stores and batteries will be required for it, but as I said at the beginning, much it's more interesting to do something with your own hands than just buy.

Greetings, dear readers. In today’s article we’ll talk about today’s hot technology – wireless charging for phones. You've probably heard how branded companies focus on it when introducing the next portable device with its support. Not wanting to spend their hard-earned money, many remain with their old mobile phone, never ceasing to dream of trying out wireless charging.

Wireless charging do it yourself - very simple and sufficient quick solution. Read the instructions and watch the video. Interesting, right? Then let's go in order. But be sure to read the advice at the end of the article!

Anything new? No, the long-known “old”

When I first saw wireless charging, I thought that manufacturers had made a breakthrough by opening some kind of new technology. Fortunately, there is the Internet, which told me the truth. In fact, the advent of wireless energy transmission was made possible thanks to the discovery of André Marie Ampère's law, which proved that electric current produces a magnetic field.

And this happened, for a moment, almost 200 years ago. In subsequent years, a number of scientists confirmed the existence of electromagnetic waves, and Nikola Tesla devoted years of his life to studying the possibility of transmitting energy over a distance. Using electromagnetic induction, the physicist was able to light an incandescent lamp from a distance.

Standard Qi

Of course wireless transmission energy was interesting in many areas of human life, but for a long time did not go beyond the walls of the laboratories. Already in this century, companies that develop consumer electronics(tablets, smartphones), they began to take initiatives to create wireless chargers. A huge contribution was made by the Wireless Power Consortium, which developed the Qi standard for low currents.

The standard specification was free and accessible, so it very soon began to be used in portable equipment. Three years later, Qi acquired a specification for medium currents. There are other standards, but they are more complex than Qi and less common. More recently, in 2015, scientists at the University of Washington discovered that energy can be transmitted via Wi-Fi networks. We are waiting for the smartphone to charge by connecting to the router.

How Qi wireless charging works

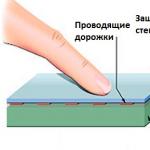

Well, already from the name of the device it becomes clear that the gadget does not require connecting wires to transfer energy. The operating principle is very simple. The charger has a built-in coil (copper), which takes on the role of creator and transmitter of the electromagnetic field already on the receiver coil placed in the smartphone (can be above the battery or back cover). Electromagnetic radiation occurs when a mobile phone with a receiver is in close proximity to the transmitter (usually about 4 centimeters). Then the capacitors and rectifier (low-power semiconductor diode) get to work, which provide the battery with energy.

So, can I do wireless charging myself?

Yes, this doesn’t even require any special knowledge of electrical engineering. Moreover, enthusiasts had already conducted similar experiments before us, posting detailed instructions and diagrams for assembling wireless charging with your own hands. If all the necessary components are at hand, then creating the simplest wireless charging will not take even an hour. However, we recommend that you first practice on old “push-button” devices, and not rush to “invent” charging for brand new iPhone. For example, you can assemble such a thing for your Nokia, whose charging socket has fallen off, resuscitating it in this way. So let's get started.

Instructions: how to make wireless charging for your phone with your own hands

The whole process can be divided into two parts: manufacturing the transmitter and the receiver. The first component will be a separate device, and the second will be installed on the phone.

The wireless charging circuit is very simple, consisting of two coils (transmitter and receiver), as well as a transistor and resistor.

Transmitter device:

- To begin with, we take a frame, the diameter of which should be 7-10 centimeters, but you can have another one - at your discretion.

- Now you will need copper wire with a diameter of 0.5 mm. This is what we wrap around the frame. It is necessary to make 20 turns, then make a tap and twist another 20 turns in the opposite direction.

- You will need a transistor. You can use any, be it polar or bipolar - there is not much difference. If there is direct conduction, then you will have to change the polarity. The transistor is connected to the end of the coil and the tap.

- We fasten the resulting structure with tape or another type of insulation. To make everything look “solid”, you can use DVD or CD boxes. Some craftsmen even bother cutting out, so to speak, wooden bodies.

- To provide power you can use standard adapter 5 Volt power supply, which is connected to the circuit.

- Everything, the device that will transmit electricity is ready.

Now let's move on to making the receiver:

- If making a transmitter takes a few minutes, then you will have to work hard with the receiver. First you have to make a coil, but a flat one. You will need copper wire, but with a smaller diameter - 0.3-0.4 mm. You will need to make 25 turns. For convenience, I advise you to use some kind of lining, for example a piece of plastic. We gradually strengthen the coils with superglue so that the structure does not fall apart - you will have to wind it again. At the end of the work, you must carefully tear the receiver away from the plastic on which it was wound.

- Now we connect our receiver to the battery via a high-frequency silicon diode, for example SS14. The coil should be on the top of the battery, closer to the cover. To stabilize the voltage, a capacitor should be used.

- You can connect the receiver either to the charging connector or directly to the battery. The latter option is perfect for users whose charging port has died.

- That's it, we're closing back cover so as not to move the coil.

For many users, I think a video on how to make wireless charging with your own hands would be helpful. So here you go:

With this, your DIY wireless charger is ready. To start using it, just place your phone on the transmitter. To date, more than a dozen instructions for assembling wireless chargers have accumulated on the Internet. The principle is approximately the same, but enthusiasts continue to improve this device, introducing something of their own. True, it is better for beginners to first practice with the simplest option presented in the instructions, so that they do not have to take the phone for repair.

Suitable for any device

The most important advantage of DIY wireless charging is the ability to make it for almost any device: smartphone, regular phone, camera, radio and so on. The power principle of all these gadgets is similar, so charging follows the same scenario.

True, I strongly do not recommend trying to make wireless charging with your own hands for expensive smartphones. Firstly, you will have to disassemble the case to connect the receiver coil, since modern models often made non-separable (it is not possible to simply remove the cover). Secondly, if you mix something up, you risk damaging the device, especially for beginners. Thirdly, most modern smartphones support wireless charging from the factory or are provided by other manufacturers.

Disadvantages of DIY wireless charging

do you need it?

do you need it? Smoothly we came to a very important point– the disadvantages of homemade wireless chargers. Yes, it is possible to do without extra costs interesting and useful device– great, but let’s not forget about the risks you are taking.

- Errors during manufacturing will, at best, lead to the fact that wireless charging will not work; at worst, the phone will not work.

- Don't expect your smartphone to charge quickly. Even factory wireless chargers still lag behind conventional chargers in terms of charging speed, let alone those made by yourself.

- I don’t think that every house has a coil of wire, a diode and a couple of transistors. You will have to buy all this, spending an amount comparable to that required to buy a ready-made, albeit Chinese, device.

What can I add? Do-it-yourself wireless charging is more of a way to visually look at the principle of operation of the electromagnetic field. To assemble a truly worthwhile and beautiful device, you will need to spend a lot of time and money. It is more profitable to order a ready-made kit without wasting time on winding the circuit. Of course, if you are a fan of creating something unusual with your own hands, then be sure to start developing “your own” wireless charger.

Photo: Koolpad Qi

Photo: Koolpad Qi What should those who don’t want to spend time assembling wireless charging do it themselves? It’s simple - we order a ready-made kit, which is already more or less well assembled at the factory. The cost, as a rule, does not exceed 300 rubles, and the kit already includes both a transmitter and a receiver. Wireless chargers are sold in electronics stores, but it is more profitable to order from Chinese online stores.

Note that many modern smartphones are equipped by the manufacturer with a receiver (receiver). Therefore, owners of these models do not need to purchase anything additional (in exceptional cases, sellers may not include a docking station (transmitter) in the kit). The list of such devices is quite extensive:

- Samsung (Note 5, S6/S6 Duos and later models)

- Google Nexus 4/5/6/7

- LG G3 and new flagships

- Blackberry 8900

- Nokia Lumia (810-930)

- Yotaphone 2

The list includes the most common models, but not all. In addition, it is regularly updated with new devices. To find out if your smartphone supports wireless charging, look for the “Qi” designation in the model specifications. Information must also be present on the manufacturer’s website.

My smartphone does not support wireless charging

If your device does not have a built-in receiver, do not rush to get upset - Chinese “friends” have taken care of users by releasing both special receivers for certain models and universal receivers. About the first type, I think everything is clear. Usually, they indicate which smartphone model it is intended for. But the second type of receiver is more interesting. Such receivers are not tied to a specific smartphone, so they can be installed in almost any one. However, it should be taken into account that universal receivers are divided into several classes:

- Film with special contacts. Fits under the phone cover without affecting functionality. The device must have contacts near the battery for its installation. The main advantage is that the charging socket remains free.

- Apple receiver. This type is intended for Apple devices with a Lightning connector, that is, all current models.

- Android receiver. Designed for smartphones with a microUSB connector. Since there are plenty of Android smartphones, and the manufacturer places the charging socket as he wants (and where he wants), you should look at specific model. As a rule, microUSB is located on the lower or upper end, and is of type “A” (connector in the form of a regular trapezoid, when looking at the smartphone with the screen up), “B” (irregular trapezoid) or “C” (oval).

The docking station (transmitter) does not play a special role - you can even use more than one kit or a completely different form. Therefore, the receiver and charging pad can be purchased separately, which will help save a little more.

In addition to receivers that need to be mounted on a lid or hidden under it, cases with a built-in receiver are available for sale. Of course, they are not universal, so you can’t find one for every smartphone. And they don't look the best in the best possible way. Be that as it may, many may still be interested in this look.

Models of ready-made wireless chargers

So, we come to buying a wireless charger from Chinese online sites. You can, of course, go to an electronics store that sells better models, but you will have to pay significantly more. Therefore, we go to one of the stores on the Internet, where we look for something like “universal wireless chargers.” Here you will meet a bunch of models. Then you have several options:

- Purchasing a complete set. In this case, you get both a receiver (receiver) and a charging pad. Upon receipt, all you have to do is connect everything.

- Purchasing parts separately. Perhaps you already have a receiver, but the docking station is broken (or vice versa). In order not to waste money, you can order only what you need.

- Purchasing components for self-assembly. Some sellers provide the base (coils, boards, transistors, etc.) so that the user can assemble whatever his heart desires.

You can’t single out popular companies because sellers don’t even list them. And if the manufacturer is indicated, then the name says absolutely nothing (some kind of Chinese company). And it’s stupid to bother finding a good manufacturer - the cost of wireless charging is usually ridiculous. Plus, customer reviews indicate that the defect rate is quite low.

I was thinking and scoured the Internet: “why can’t you make your own wireless charging with your own hands + at home?” And in today’s article I will review instructions for making wireless charging at home. Please, if you are interested, go under the cut!

INSTRUCTIONS FOR ADVANCED! Materials are extremely difficult to find!

If you look at the wireless charging system (wireless charging), you can see the main, so to speak, components in it. This:

- Transmitter

- Receiver

Yes, sir! What do we need to create it? And we will need the following materials:

I recommend that you assemble the circuit using a hinged mounting, without using a printed circuit board, and also use transistors of the cooling radiator, on which there is a small fan. The transmitting coil should have a diameter of 10 cm and consist of 6 turns of wire. Wire diameter - 6 mm. And, by the way, there should be a slight deviation from the middle. A take-up coil must also be used. It is not particularly different from the transmitter. Unless there should be 3 turns there, and a branch from the middle is useless.

I recommend that you assemble the circuit using a hinged mounting, without using a printed circuit board, and also use transistors of the cooling radiator, on which there is a small fan. The transmitting coil should have a diameter of 10 cm and consist of 6 turns of wire. Wire diameter - 6 mm. And, by the way, there should be a slight deviation from the middle. A take-up coil must also be used. It is not particularly different from the transmitter. Unless there should be 3 turns there, and a branch from the middle is useless.  Be careful! When assembling such a charge, it is necessary to use a capacitor. Its capacity must be equal to the transmitter's capacity. Be sure to check, test and experiment with the number of turns and the diameter of its winding

Be careful! When assembling such a charge, it is necessary to use a capacitor. Its capacity must be equal to the transmitter's capacity. Be sure to check, test and experiment with the number of turns and the diameter of its winding Because portable devices are a necessity in modern everyday life, they may be subject to overuse, improper charging, or normal wear and tear.

This article has an amazing idea on how to make with my own hands a simple portable phone charger. Assembling such a device will not be difficult and inexpensive; for this you will need a soldering iron, flux, solder, a 9-volt Krona battery, a battery connector, a USB connector, an L7805 voltage stabilizer and, of course, a small box from Tic Tac, in which all the electronic stuffing will be placed. If you don’t dare to make a homemade product, then take a look at this Chinese store.

The voltage stabilizer has three wires. First, the entrance. The second is mass, the third is output. The numbers 05 in the marking of this device mean that the output will be 5 volts.

First you need to solder the output of the stabilizer, and this is the right leg, to the plus of the USB connector. After this we need to solder the middle pin to the negative terminal. Finally, we solder the positive wire from the crown connector to the first leg of the stabilizer. This is his entrance. We connect the second wire from the crown connector, with a minus, to the second leg of the stabilizer, that is, to the minus and to ground.

Now all this can be placed in a tic-tac box. Let's test the portable charger. We will make all the necessary connections. And we see that the charge indicator shows that the phone has begun to be powered by this autonomous device. Of course, such a charge will not last long, so for long-term use you need to take a battery crown.

You might be interested, which can be used as a device with the function that was described in our article.

DIY USB Charger WITH MINTY BOOST

WE ARE LUCKY that we live in a time when portable electronic devices allowing us to do things that a spaceship full of science fiction writers couldn't even dream of a few decades ago. The only one iPhone disadvantage, Nintendo DS, Kindle, etc. – their constant need to recharge. And it seems that no matter how careful you are to rise above it before your trip, you can always end up not working at the most inconvenient moment. Of course there are cables DC for car, plugs on commuter trains and even USB charging plugs at airports, but there are a million other places where you'll find you don't have fast charging options.

Admittedly, this is hardly even first world problem , but it's certainly a challenge for GeekDad, who loves to solve problems.

Then what's the solution? Well we could buy a mass solution like Philips USB Power Station , but it's a bit expensive and seems like too easy an answer. So what would McGeever do in this situation? Of course he builtMinty Boost charger !

Minty Boost Kit contains printed circuit board and all the parts needed to assemble a portable USB charger that runs on regular AA batteries. The kit requires soldering to assemble, which may be a problem for some. This is, however, a fairly simple project, andinstructions in AdaFruitfantastic. If you're looking for your first soldering project, this is a great choice.

I had my Minty Boost assembled in about an hour and didn't even manage to burn myself for a change. Here are some examples of actions:

Once the basic assembly was complete, it was a simple matter of popping in a couple of AA batteries and testing everything out. When I first checked the output with a multimeter, the output voltage was a little low at 4.8 V. This turned out to be due to the almost dead AA batteries I was using. After I replaced them with new batteries, the output voltage was above 5.0V as expected.

Modern technologies are designed in such a way that sometimes one minor breakdown can cost a huge amount of money for repairs, or restoration will be impossible and you will simply have to buy a completely new mobile phone. Not such a pleasant trend, is it? And if you look at the general statistics of breakdowns, it turns out that most mobile phone models are primarily susceptible to breakdown in the area of the charger, completely breaking the connector. And this is a rather unpleasant situation that needs to be resolved urgently.

Fortunately, there is a solution and it is to create wireless charging for your mobile phone. But let us immediately note that for this you need to understand a little about electronics or try to follow our recommendations, which will be given below. And if you succeed, then this problem will never bother you again.

Why is such development needed?

Do-it-yourself wireless charging is not only a great way to solve many problems in terms of restoring performance mobile device, but also a great opportunity to just experiment. If you figure it out and understand what the peculiarity of this invention is, you will certainly be able to feel like an inventor and possibly solve many problems of breakdowns in the future. But let’s not focus too much on this point and just look at how to make wireless charging for your phone.

Required material

Charging a phone with your own hands requires not only increased attention from a person, but also a comprehensive and careful implementation of all the necessary actions that will allow you to achieve the planned result. At the same time, it is worth understanding that without a specific electronics design scheme, it will not be possible to achieve the desired result. In this case, you will also need additional material, which includes:

- Power unit. A link capable of generating and converting energy from a standard power source.

- Transistor IRL3705.

- Resistor 100 Ohm.

- Diode SS14.

- Copper wire 0.3 and 0.5 mm. This component is a connecting element that will allow you to use your new invention.

Let us immediately note that the listed set is minimally basic, therefore, during the design process, additional needs for tools or material may arise, but this already depends on the specifics of the process itself.

Creating a wireless charging design

Once you have collected all required material for the invention, it will be possible to begin assembly. First, carefully study the diagram, which will serve as the basis for creating your assembly:

It shows that the new design uses the induction method of energy transfer. Using a special copper wire, energy is transmitted contactlessly using special transmitters, from which we will begin assembling the invention.

In principle, if you have read the diagram and already understand what goes for what, then you can start making a transmitter. In fact, the design itself is not so complicated, you attach the material one by one and, using wire, create the first transmitter to supply energy. To do this, take a wire with a diameter of 0.5 mm and begin to wind it in the form of a frame. It is advisable to create 40 turns, the process should occur from the middle. We recommend that you first make 20 turns and create a tap, and then make another 20 additional turns and create a tap again. In principle, if you look at the drawing, there is nothing complicated about it.

Next we connect the transistor to our transmitter. You can use absolutely any model for this, the main thing is that the base rating of this element is in the region from 22 to 830 Ohms. And to show clearly how exactly all these devices should be assembled, we suggest that you familiarize yourself with the drawing; it clearly demonstrates exactly how the structure should look.

Visual representation of the design basis

Visual representation of the design basis It is worth understanding that the main power source of the entire structure is the power supply, so first you should create the structure itself, and only when everything is ready to connect it to the power supply, provided that it is turned off. And once everything is connected and ready, you can safely experiment.

The last step in creating the design is to create a receiver on your mobile phone. In this case, you also need to create a round set of turns, and then fasten the structure to the mobile phone battery. The turns themselves should be created using 0.3-0.4 mm copper wire and secured better with super glue so that they do not unwind and can remain assembled for a long time.

After creating the base, you need to connect the lead to the phone battery using an SS14 diode. And so that you don’t get confused and understand exactly how to do this, we suggest you pay attention to the drawing.

Be sure to create a coil of wire for the phone and connect it to the battery

Be sure to create a coil of wire for the phone and connect it to the battery That's all you need to know about this invention. The induction method is probably clear to you, and we think there is no need to explain exactly how to use contactless energy generation. Note that the initial power of such charging is not high and it will take 6 to 10 hours of waiting for the phone to be fully charged. But if you want to increase the charging speed and power, you will need a more powerful power supply and thicker copper wire if you build a transmitter.

Now you have personal instructions on exactly how to create a wireless charger to charge your phone. Perhaps after the first reading you may have some misunderstandings, but during the process of practical testing you yourself will be able to figure out exactly how to construct this device. In field conditions, of course, it will be difficult to organize such a method, since in any case you need a constant power source, but it will be quite possible to free up your space from unnecessary wires. Therefore, you can safely use it and gain experience in design.