This project was conceived as a way to test the suitability of a capacitor for operation. I buy a lot of old electronic devices over 25-60 years old and the condition of electrolytic capacitors is suspicious. I needed a quick way to test capacitors.

What is ESR?

"ESR" stands for Equivalent Series Resistance. ESR is one of the characteristics that determine the performance of an electrolytic capacitor. The lower the ESR of a capacitor, the better, because at high ESR, the capacitor heats up when current passes through it, and this destroys it. Over time, the ESR of a capacitor can increase from 10 to 30 times, or the capacitor will no longer pass current at all. The typical life of electrolytic capacitors is 2000-15000 hours and is very dependent on the ambient temperature. As the ESR increases, the capacitor becomes less efficient and eventually the circuit fails.

WhyESRis the meter useful?

Most ESR meters require the capacitor to be desoldered from the circuit. When there are a lot of capacitors in the circuit, it is very tiring, and there is a risk of damaging the board. This tester uses low voltage (250mV) high frequency (150kHz) to measure capacitors. Measurement without soldering out of the circuit is possible due to the low voltage that the capacitor has enough, but it is not enough for other parts, so they do not interfere with the measurement. Most ESR meters will be damaged if you measure a charged capacitor with them. This circuit can withstand up to 400V charge on the capacitor ( This voltage is life-threatening. Be careful!). My experience has shown that the ESR meter recognizes about 95% of bad capacitors.

Characteristics of the ESR Meter:

- measurement of electrolytic capacitors > 1uF

- the polarity of the capacitor is not important

- allows connection of charged capacitors up to 400V

- low power consumption (about 25 mA), which gives about 20 hours of battery life when using 4 AA batteries

- measurement of ESR in the range of 0-75 ohms.

Circuit Description

The circuit starts with a 150 kHz oscillator on a single 74hc14 element. The remaining elements are used to increase the voltage going to the low-pass filter. A low pass filter is needed because the square wave contains a lot of noise and harmonics. The signal from the filter goes to a 10 ohm resistor, which provides a low signal level when measuring the capacitor. Diodes D5 and D6 protect the circuit from discharge when a charged capacitor is connected. R18 is the quenching resistor for C5. C5 protects the circuit from DC current up to 400V.

The rest of the circuit is a transistor amplifier with a gain of about 10.5. This amplifies the signal coming from the capacitor to a few volts in amplitude. The amplified voltage must be large enough to overcome 2 diodes, after which the scale will begin to respond. The correct functioning of the circuit can be checked by connecting resistors of different resistances to the input (1 ohm - about 90% of full scale, 10 ohms - about 40% of the scale and 47 ohms - about 10% of the scale). Tester readings may vary slightly depending on temperature. Below you can download photos and a drawing of the PP.

Project files:

Assembly drawing - esrbuildit.png

PP bottom view - esrpcb.png

PP bottom view - esrxray.png

PP and diagram in the format - ESR meter.zip

/SWCadiii-esr.asc

List of radio elements

| Designation | Type | Denomination | Quantity | Note | Score | My notepad |

|---|---|---|---|---|---|---|

| IC1 | buffer ICs, drivers | CD74HC14 | 1 | To notepad | ||

| Q1 | bipolar transistor | 2N2222 | 1 | To notepad | ||

| D1-D4 | rectifier diode | 1N4148 | 4 | To notepad | ||

| D5, D6 | rectifier diode | 1N4004 | 2 | To notepad | ||

| C1-C3 | Capacitor | 0.01uF | 3 | To notepad | ||

| C4 | Capacitor | 0.047uF | 1 | To notepad | ||

| C5 | Capacitor | 0.47uF 400V | 1 | To notepad | ||

| C6 | Capacitor | 0.1uF | 1 | To notepad | ||

| C7 | electrolytic capacitor | 10 uF | 1 | To notepad | ||

| R1 | Resistor | 1 kOhm | 1 | To notepad | ||

| R2-R6 | Resistor | 680 ohm | 5 | To notepad | ||

| R7, R8 | Resistor | 10 ohm | 2 | To notepad | ||

| R9 | Resistor | 100 kOhm | 1 | To notepad | ||

| R10 | Trimmer resistor | 25 kOhm | 1 | To notepad | ||

| R11 | Resistor | 2.2 kOhm | 1 | To notepad | ||

| R12 | Resistor | 100 ohm | 1 | To notepad | ||

| R17 | Resistor |

ESR of capacitors of different types

Naturally, it is impossible to control the equivalent series resistance of a capacitor with an ordinary Ohmmeter - a special device is needed here. There are several simple designs of ESR meters on the Internet, but if you wish, you can assemble a more accurate and convenient meter on a microcontroller. For example from the magazine Radio 7-2010.

The circuit of the ESR meter of capacitors on

Attiny2313

All necessary files and firmware are in the archive. After assembling and turning on, turn the contrast control until an inscription in two lines appears on the LCD screen. If it is not there, we check the installation and correctness of the firmware of the MK ATtiny2313. If everything is OK - press the "Calibration" button - the firmware will be corrected for the response speed of the input part of the meter. Next, you will need several new high-quality electrolytic capacitors with a capacity of 220 ... 470 microfarads of different batches, best of all - for different voltages. We connect any of them to the input jacks of the device and begin to select the resistor R2 within 100 ... 470 ohms (I got 300 ohms; you can temporarily use a constant + tuning chain) so that the capacitance value on the LCD screen is approximately similar to the value of the capacitor . For the time being, it is not worth striving for great accuracy - it will still be corrected; then check with other capacitors.

To set up an ESR meter, you need a table with typical values \u200b\u200bof this parameter for different capacitors. This label is recommended to be affixed to the body of the instrument under the display.

The following table lists the maximum equivalent series resistance values for electrolytic capacitors. If it is higher for the measured capacitor, then it can no longer be used to work in the smoothing filter of the rectifier:

We connect a 220 uF capacitor and, by a slight selection of the resistance of resistors R6, R9, R10 (marked with asterisks in the diagram and on my assembly drawing), we achieve Esr readings close to those indicated in the table. We check on all available prepared reference capacitors, incl. you can already use capacitors from 1 to 100 microfarads.

Since the same section of the circuit is used to measure the capacitance of capacitors from 150 μF and for the ESR meter, after selecting the resistance of these resistors, the accuracy of the readings of the capacitance meter will slightly change. Now you can adjust the resistance of the resistor R2 to make these readings more accurate. In other words, you need to select the resistance R2 - to clarify the readings of the capacitance meter, adjusting the resistors in the comparator divider - to clarify the readings of the ESR meter. Moreover, priority should be given to the internal resistance meter.

Now you need to set up a capacitor capacitance meter in the range of 0.1 ... 150 microfarads. Since a separate current source is provided for this in the circuit, the capacitance measurement of such capacitors can be made very accurate. We connect small capacitors to the input jacks of the device and, by selecting the resistance R1 within 3.3 ... 6.8 kOhm, we achieve the most accurate readings. This can be achieved if not electrolytic, but high-precision K71-1 capacitors with a capacity of 0.15 μF with a guaranteed deviation of 0.5 or 1% are used as reference ones.

When I assembled this ESR meter, the circuit started up immediately, only calibration was needed. This meter has helped many times in the repair of the PSU, so the device is recommended for assembly. The scheme was developed DesAlex , collected and tested: sterc .

Discuss the article ESR METER ON MICROCONTROLLER

We are already accustomed to the main parameters of the capacitor: capacitance and operating voltage. But recently, its equivalent series resistance (ESR) has become an equally important parameter. What is it and what does it affect?

Since EPS most strongly affects the operation of electrolytic capacitors, in the future we will talk about them. Now we will analyze the electrolytic capacitor by bones and find out what secrets it hides.

Any electronic component is not perfect. This also applies to the capacitor. The totality of its properties is shown by a conditional diagram.

As you can see, a real capacitor consists of a capacitance C , which we are used to seeing on diagrams in the form of two vertical stripes. Next resistor Rs , which symbolizes the active resistance of the wire leads and the contact resistance of the lead - lining. The photo shows how the wire leads are attached to the plates by riveting.

Since any, even a very good dielectric, has a certain resistance (up to hundreds of megaohms), a resistor is shown parallel to the plates Rp . It is through this "virtual" resistor that the so-called leakage current flows. Naturally, there are no resistors inside the capacitor. This is for illustration and convenience purposes only.

Due to the fact that the plates of the electrolytic capacitor are twisted and installed in an aluminum case, an inductance is formed L.

This inductance exhibits its properties only at frequencies above the resonant frequency of the capacitor. The approximate value of this inductance is tens of nanohenries.

So, from all this, we select what is included in the EPS of an electrolytic capacitor:

Resistance, which is caused by losses in the dielectric due to its inhomogeneity, impurities and the presence of moisture;

Ohmic resistance of wire leads and plates. Active resistance of wires;

Contact resistance between plates and leads;

This can also include the resistance of the electrolyte, which increases due to the evaporation of the electrolyte solvent and changes in its chemical composition due to its interaction with the metal plates.

All these factors are summed up and form the resistance of the capacitor, which was called the equivalent series resistance - abbreviated as EPS, but in a foreign manner ESR (E equivalent S serial R existence).

As you know, an electrolytic capacitor, due to its design, can only work in DC and pulsating current circuits due to its polarity. Actually, it is used in power supplies to filter ripples after the rectifier. Let's remember this feature of the capacitor - to pass current pulses.

And if ESR is, in fact, resistance, then heat will be released on it during the flow of current pulses. Think about the power of the resistor. Thus, the larger the EPS, the more the capacitor will heat up.

Heating an electrolytic capacitor is very bad. Due to heating, the electrolyte begins to boil and evaporate, the capacitor swells. Probably, you have already noticed a protective notch on the top of the case on electrolytic capacitors.

With prolonged operation of the capacitor and an elevated temperature inside it, the electrolyte begins to evaporate and put pressure on this notch. Over time, the pressure inside increases so much that the notch breaks, releasing gas out.

"Slammed" capacitor on the power supply board (reason - exceeding the permissible voltage)

Also, the protective notch prevents (or weakens) the explosion of the capacitor when the permissible voltage is exceeded or its polarity is changed.

In practice, it happens the other way around - the pressure pushes the insulator away from the terminals. The photo below shows a capacitor that has dried up. Its capacitance decreased to 106 uF, and the ESR when measured was 2.8Ω, while the normal ESR value for a new capacitor with the same capacitance lies in the range of 0.08 - 0.1Ω.

Electrolytic capacitors are produced at different operating temperatures. For aluminum electrolytic capacitors, the lower temperature limit starts from -60 0 C, and the upper limit is +155 0 C. But for the most part, such capacitors are designed to operate in the temperature range from -25 0 C to 85 0 C and from -25 0 C to 105 0 С. Sometimes only the upper temperature limit is indicated on the label: +85 0 С or +105 0 С.

The presence of EPS in a real electrolytic capacitor affects its operation in high-frequency circuits. And if for ordinary capacitors this influence is not so pronounced, then for electrolytic capacitors it plays a very important role. This is especially true for their operation in circuits with a high level of ripple, when a significant current flows and heat is generated due to ESR.

Take a look at the photo.

Swollen electrolytic capacitors (due to prolonged operation at elevated temperatures)

This is the motherboard of a personal computer that has stopped turning on. As you can see, there are four swollen electrolytic capacitors on the printed circuit board next to the processor heatsink. Long-term operation at elevated temperatures (external heating from a radiator) and a decent service life led to the fact that the capacitors “slammed”. This is due to heat and ESR. Poor cooling negatively affects not only the operation of processors and microcircuits, but, as it turns out, also electrolytic capacitors!

Reducing the ambient temperature by 10 0 C prolongs the service life of the electrolytic capacitor by almost half.

A similar picture is observed in failed PC power supplies - electrolytic capacitors also swell, which leads to a drawdown and ripples in the supply voltage.

Faulty capacitors in the ATX PC PSU (caused by poor quality capacitors)

Often, due to long-term operation, switching power supplies for access points, Wi-Fi routers, and all kinds of modems also fail due to “slammed” or lost capacitors. Let's not forget that when heated, the electrolyte dries up, and this leads to a decrease in capacity. I described an example from practice.

From all that has been said, it follows that electrolytic capacitors operating in high-frequency pulse circuits (power supplies, inverters, converters, switching stabilizers) operate in rather extreme conditions and fail more often. Knowing this, manufacturers produce special series with low ESR. On such capacitors, as a rule, there is an inscription Low ESR , which means "low EPS".

It is known that the capacitor has capacitive or reactance, which decreases with increasing frequency of the alternating current.

Thus, as the AC frequency increases, the reactance of the capacitor will drop, but only until it approaches the value of the equivalent series resistance (ESR). That is what needs to be measured. Therefore, many devices - ESR meters (ESR-meters) measure ESR at frequencies of several tens - hundreds of kilohertz. This is necessary in order to "remove" the reactance value from the measurement results.

It is worth noting that the ESR value of a capacitor is affected not only by the current ripple frequency, but also by the voltage on the plates, ambient temperature, and workmanship. Therefore, it is impossible to say unequivocally that the ESR of a capacitor, for example, is 3 ohms. At different operating frequencies, the ESR value will be different.

ESR meter

When checking capacitors, especially electrolytic ones, you should pay attention to the ESR value. There are many commercially available instruments for testing capacitors and measuring ESR. The photo shows a universal radio component tester (LCR-T4 Tester), the functionality of which supports measuring the ESR of capacitors.

In radio engineering magazines, you can find descriptions of home-made devices and attachments for multimeters for measuring ESR. You can also find highly specialized ESR meters on sale that are capable of measuring capacitance and ESR without soldering them out of the board, as well as discharging them before that in order to protect the device from damage by the high residual voltage of the capacitor. Such devices include, for example, such as ESR-micro v3.1, ESR-micro V4.0s, ESR-micro v4.0SI.

When repairing electronics, you often have to change electrolytic capacitors. At the same time, parameters such as capacitance and ESR are measured to assess their quality. In order to have something to compare with, an ESR table was compiled, which indicates the ESR of new electrolytic capacitors of different capacities. This table can be used to evaluate the suitability of a particular capacitor for further service.

Despite the fact that most modern multimeters are equipped with a measurement function, including electrolytic ones, however, the ability to measure ESR (equivalent series resistance) is actually very rare.

In this design, the generator is assembled on one logic element (DD1.1) of the 74HC14N chip (inverting Schmitt) and the RC circuit R1 and C1, which determines the frequency of the generator. In this case, it is about 100 kHz. The signal from the generator is amplified by the remaining five elements of the DD1 microcircuit to an amplitude in the region of 250mV, which is then fed to the investigated Cx.

The capacitor under test is connected to the contacts X1 and X2 of the ESR meter. To protect the tester from the charge present in the capacitor Cx, a protection line is provided consisting of C4, R8, VD1 and VD2 (). The measured signal after passing through the capacitor Cx is amplified by T1 (), then rectified by four D3-D6 (), and then filtered by the capacitor C6.

A microammeter with a total deviation scale of about 50 μA is connected to terminals X3 and X4 through R14. The value displayed on the indicator is basically proportional to the ESR value of the capacitor. Of course, it is necessary to calibrate the ESR value and the capacitance of the new capacitor by calibration, so that a mismatch with a failed capacitor can be detected.

ESR Meter Calibration

A correctly assembled and error-checked ESR meter should work the first time you turn it on. As a power source, you can recommend a power supply for. After applying power, the device should immediately show the ESR value. To obtain more accurate values, you can connect a 25 kΩ instead of a constant resistor R14.

The setup is simple - instead of the capacitor under study, it is necessary to connect resistors with low resistance in turn. The scale marking should be something like this: when a 1 ohm resistor is connected, the arrow deviation should be more than 90%, with a 10 ohm resistor, the deviation is around 40% and at 47 ohms only 10%.

For your information, the real resistance (ESR) of the working electrolytic capacitor should not exceed 10 ohms.

Often when repairing electronics, you have to change swollen capacitors. If the capacitor is swollen, this indicates a decrease in its capacitance and an increase in equivalent series resistance (ESR). It happens that the capacitor is not swollen, and its ESR is more than normal, in this case I assembled a device from MasterKit and checked suspicious capacitors with it. At a certain point, it became interesting what he actually measures and how he does it.

What is ESR.

The equivalent simplified capacitor circuit consists of a resistor and a capacitor, the value of this resistance is measured by the device. It remains to figure out how he does it.

Let's connect a signal generator to the capacitor, its equivalent circuit is shown in the figure, it consists of a generator and a series-connected resistor equal to the output resistance of the generator.

Now let's connect a good 470uF capacitor and see what the oscilloscope shows.

What changed? The amplitude that the device measures has correctly increased, and the series-connected resistance in the equivalent circuit of the capacitor is responsible for its value.

Let's try to calculate it. The equivalent series resistance of the capacitor is considered, like a conventional divider. The reactance of the capacitor can be neglected since the pulse duration is much less than tau.

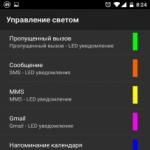

Let's calculate the ESR value for a good capacitor, it is equal to 0.65 Ohm. Let's compare it with what the MasterKit device shows, the accuracy of this device is not high, but it will do for a rough estimate.

The first LED lights up, the switch is in the 1:1 position, we look at the table, the resistance is 1.3 Ohm.