Attention! The following technique is only valid for measuring speakers with resonant frequencies below 100Hz, at higher frequencies the error increases.

To obtain the most reliable results, all measurements are recommended to be performed several times (3-5 times), then the arithmetic mean value is taken as the result.

Before measuring the parameters, the speaker must be “stretched”. The fact is that for a speaker that has not been working for a certain time or for a new speaker, the parameters will differ from those that we will measure after the speaker has played for a certain time and will work regularly. Therefore, the meaning of stretching the speaker is to obtain reliable measurement parameters. There are many opinions on how and how much to knead: just music, a sine signal (sine) at the resonance frequency of the speaker Fs, a sine at 1000 Hz, drive a sine at different frequencies, white and pink noise, use test disks.

How to knead is up to you - this is a matter of your capabilities and time, but kneading is a must.

From myself, I advise you to knead during the day in various combinations of the above methods, it’s worth starting with the sine of the natural resonance frequency Fs (taken from the speaker’s passport) for the maximum amount of time, then use the other methods. You can use test discs, preferably those that contain both musical and technical tracks, i.e. generated signals of various shapes, frequencies and powers, and it is better to start with technical tracks. It is advisable to knead the speaker by 50-100% of the rated power, it all depends on your conditions, ears and nerves.

The most basic parameters by which acoustic design (body, box) can be calculated and manufactured are the Thiel-Small parameters.

Measurement of the resonant frequency Fs, the quality factor of the speaker Qts and its components of the electrical and mechanical quality factors Qes, Qms.

Method 1

To measure these parameters, you will need the following equipment:

* Voltmeter

*Audio signal generator

*Frequency meter

* Powerful (at least 2 watts) 1000 ohm resistor

* Accurate (+- 1%) 10 ohm resistor

* Wires, clips and other rubbish to connect it all into a single circuit.

Of course, this list is subject to change. For example, most oscillators have their own frequency scale and a frequency counter is not necessary in this case. Instead of a generator, you can also use a computer sound card and appropriate software (for example, this one) capable of generating sinusoidal signals from 0 to 200 Hz of the required power. Or I still had to do this when there was no computer nearby: I cut tracks with frequencies from 20-120Hz onto a disc, then played it on a DVD connected to an amplifier and then connected a suspended speaker through resistance.

Calibration.

First you need to calibrate the voltmeter. To do this, instead of the speaker, a resistance of 10 ohms is connected and by selecting the voltage supplied by the generator, it is necessary to achieve a voltage of 0.01 volts. If the resistor is of a different value, then the voltage should correspond to 1/1000 of the resistance value in Ohms. For example, for a calibration resistance of 4 ohms, the voltage should be 0.004 volts.

Remember! After calibration, it is IMPOSSIBLE to adjust the output voltage of the generator (amplifier) until the end of all measurements.

Determination of Fs and Rmax.

The speaker during this and all subsequent measurements should be in free space, usually it is hung (usually on a chandelier) away from walls and various objects. The resonant frequency of a speaker is found from its peak impedance (Z-characteristic). To find it, gradually increase the frequency of the generator, starting at about 20 Hz, and look at the readings of the voltmeter. The frequency at which the voltage on the voltmeter will be maximum (a further change in frequency will lead to a voltage drop) will be the main resonance frequency for this speaker. For speakers larger than 16cm in diameter, this frequency should be below 100Hz. Do not forget to write down not only the frequency, but also the readings of the voltmeter. Multiplied by 1000, they will give the speaker impedance at the resonant frequency, Rmax, needed to calculate the other parameters.

Definition of Qms, Qes and Qts.

These parameters are determined by the following formulas.

As you can see, this is a sequential finding of additional parameters Ro, Rx and measurement of previously unknown frequencies F1 and F2. These are the frequencies at which the speaker impedance is Rx. Insofar as Rx always less Rmax, then there will be two frequencies - one is slightly less fs, and the other is slightly larger.

Determination of the head winding resistance to direct current Re.

Now, by connecting a speaker instead of a calibration resistance and setting a frequency close to 0 hertz on the generator, we can determine its resistance to direct current Re. They will be the voltmeter reading multiplied by 1000. However, Re can be measured directly with an ohmmeter.

Method 2

The measurement scheme is the same as in the first method, the elements are the same: a 1 kΩ resistor and - a generator - either an audio frequency generator capable of delivering a voltage of 10-20V, or a generator-amplifier combination that meets the same requirement. We place the speaker away from walls, ceiling and floor (it is often recommended to hang it). We connect a voltmeter to points A and C (i.e., to the output of the amplifier), and set the voltage to 10-20 V at a frequency of 500-1000 Hz.

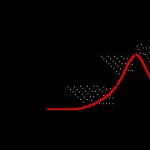

We connect the voltmeter to points B and C (i.e. directly to the speaker contacts) and by changing the frequency of the generator we find the frequency at which the voltmeter readings are maximum (as shown in the figure below). This is the natural resonance frequency of the speaker. fs. We write down fs and Us- voltmeter readings.

By changing the frequency up relative to fs, we find the frequencies at which the voltmeter readings are constant and much less Us(with a further increase in frequency, the voltage will again begin to increase, in proportion to the increase in the impedance of the speaker). Let's write this value um.

The graph of the speaker impedance in free space and in a closed box looks something like this.

We calculate the voltage U12 according to the formula: ![]()

By changing the frequency, we achieve readings on the voltmeter corresponding to the voltage U12, we find the frequencies F1 and F2.

We calculate the acoustic or mechanical quality factor according to the formula:

Electrical quality factor: ![]()

And finally, full quality: ![]()

Method 3 - Tile-small measurements with a phase inverter

The measurement scheme is the same as in the first method, the elements are the same: a calibration resistor Rk with a nominal value of 10 Ohm and an active resistance R, which sets the current in the circuit, with a nominal value of 1 kOhm. You can take the resistances Rk and R of other denominations, fulfilling the conditions:

Rk - can be anything, but close to Re

R/Re > 200

Where Re is the DC resistance of the voice coil.

Measurements begin with the most accurate determination of the DC resistance of the voice coil Re and calibration resistor Rk using a digital voltmeter or multimeter.

Then, instead of the speaker, we turn on the calibration resistor Rk and measure the voltage Uk on it. The voltage corresponding to the resistance of the voice coil to direct current is found by the formula:

Where: SD- effective radiating surface of the diffuser, m2; cms- relative rigidity.

The radiating surface of the diffuser for the lowest frequencies (in the zone of piston action), it coincides with the constructive one and is equal to: Radius R in this case, it will be half the distance from the middle of the width of the rubber suspension on one side to the middle of the rubber suspension on the opposite side. This is due to the fact that half the width of the rubber suspension is also a radiating surface. Please note that the unit of this area is square meters. Accordingly, the radius must be substituted into it in meters.

We calculate the relative stiffness Cms based on the results obtained using the formula:

M/N (meters/Newton), where M- mass of added weights in kilograms.

Determination of the equivalent volume by the additional volume method

To determine the equivalent volume of the speaker by the method of additional volume, a sealed measuring box with a round hole that matches in size with the diameter of the speaker cone. It is better to choose the volume of the box closer to the one in which we are going to listen to this speaker later. It is necessary to hermetically fix the speaker in the measuring box. It is best to do this with the magnet outward, since the speaker does not care which side it has volume on, and it will be easier for you to connect the wires. And there are fewer extra holes. seal all cracks.

Then you need to take measurements Fc(the resonant frequency of a speaker in a closed box) and, accordingly, calculate the mechanical and electrical quality factor Qmc and Qec and quality factor of the speaker in the measuring box Qts" (Qtc). After that, we already calculate the equivalent volume using the formula: ![]()

With almost the same results, you can use a simpler formula:

Where: Vb- volume of the measuring box, m3.

Checking: Computing ![]() and if measured in a box Qts'=Qtc, well, or almost equal, which means that everything is done correctly, and you can proceed to the design of the speaker system.

and if measured in a box Qts'=Qtc, well, or almost equal, which means that everything is done correctly, and you can proceed to the design of the speaker system.

findings

So, we have found and calculated several basic parameters and can draw some conclusions based on them:

*one. If the resonant frequency of the speaker is above 50Hz, then it has the right to claim to work as a midbass at best. You can immediately forget about the subwoofer on such a speaker.

*2. If the resonant frequency of the speaker is higher than 100 Hz, then this is not a low-frequency speaker at all. You can use it to reproduce mid frequencies in 3-way systems.

*3. If the ratio Fs/Qts the speaker is less than 50, then this speaker is designed to work exclusively in closed boxes. If more than 100 - exclusively for working with a phase inverter or in bandpasses. If the value is between 50 and 100, then you need to carefully look at other parameters - what type of acoustic design the speaker tends to.

It is best to use special computer programs for this, which can graphically simulate the acoustic output of such a speaker in different acoustic design. True, in this case, one cannot do without other, no less important parameters - SD, cms and Le.

The data obtained as a result of all these measurements is sufficient for further calculation of the acoustic design of a low-frequency link of a sufficiently high class.

The most basic parameters by which you can calculate and manufacture a subwoofer are:

- Speaker resonant frequency fs(Hertz)

- Equivalent Volume Vas(liters or cubic feet)

- Full quality factor Qts

- DC resistance Re(ohm)

For a more serious approach, you will also need to know:

- Mechanical quality factor Qms

- Electrical quality factor Qes

- diffuser area SD(m2) or its diameter Dia(cm)

- Sensitivity SPL(dB)

- Inductance Le(Henry)

- Impedance Z(ohm)

- peak power Pe(Watt)

- Mass of the moving system mms(G)

- Relative hardness cms(meters/newton)

- Mechanical resistance rms(kg/s)

- Motor power BL

Most of these parameters can be measured or calculated at home using not very sophisticated measuring instruments and a computer or calculator that can take roots and raise to a power. For an even more serious approach to designing acoustic design and taking into account the characteristics of the speakers, I recommend reading more serious literature. The author of this "work" does not claim to have special knowledge in the field of theory, and everything stated here is a compilation from various sources - both foreign and Russian.

Measuring Re, Fs, Fc, Qes, Qms, Qts, Qtc, Vas, Cms, Sd.

To measure these parameters, you will need the following equipment:

- Voltmeter

- Audio signal generator

- Frequency meter

- Powerful (at least 5 watts) 1000 ohm resistor

- Precise (+- 1%) 10 ohm resistor

- Wires, clamps and other rubbish to connect it all into a single circuit.

Of course, this list is subject to change. For example, most oscillators have their own frequency scale and a frequency counter is not necessary in this case. Instead of a generator, you can also use a computer sound card and appropriate software capable of generating sinusoidal signals from 0 to 200 Hz of the required power.

Scheme for measurements

Calibration:

First you need to calibrate the voltmeter. To do this, instead of the speaker, a resistance of 10 ohms is connected and by selecting the voltage supplied by the generator, it is necessary to achieve a voltage of 0.01 volts. If the resistor is of a different value, then the voltage should correspond to 1/1000 of the resistance value in ohms. For example, for a calibration resistance of 4 ohms, the voltage should be 0.004 volts. Remember! After calibration, it is IMPOSSIBLE to adjust the output voltage of the generator until all measurements are completed.

Finding Re

Now, by connecting a speaker instead of a calibration resistance and setting a frequency close to 0 hertz on the generator, we can determine its direct current resistance Re. It will be the voltmeter reading multiplied by 1000. However, Re can also be measured directly with an ohmmeter.

Finding Fs and Rmax

The speaker during this and all subsequent measurements must be in free space. The resonant frequency of a speaker is found from its peak impedance (Z-characteristic). To find it, smoothly change the frequency of the generator and look at the readings of the voltmeter. The frequency at which the voltage on the voltmeter will be maximum (a further change in frequency will lead to a voltage drop) will be the main resonance frequency for this speaker. For speakers larger than 16cm in diameter, this frequency should be below 100Hz. Do not forget to write down not only the frequency, but also the readings of the voltmeter. Multiplied by 1000, they will give the speaker impedance at the resonant frequency, Rmax, needed to calculate the other parameters.

These parameters are found by the following formulas:

As you can see, this is a sequential finding of additional parameters Ro, Rx and measurement of previously unknown frequencies F1 and F2. These are the frequencies at which the speaker impedance is Rx. Since Rx is always less than Rmax, then there will be two frequencies - one is slightly less than Fs, and the other is somewhat larger. You can check if your measurements are correct with the following formula:

If the calculated result differs from the previously found by more than 1 hertz, then you need to repeat everything from the beginning and more accurately.

So, we have found and calculated several basic parameters and can draw some conclusions based on them:

- If the resonant frequency of the speaker is above 50Hz, then it has the right to claim to work as a midbass at best. You can immediately forget about the subwoofer on such a speaker.

- If the resonant frequency of the speaker is higher than 100 Hz, then this is not a low-frequency speaker at all. You can use it to reproduce mid frequencies in 3-way systems.

- If the Fs / Qts ratio of the speaker is less than 50, then this speaker is designed to work exclusively in closed boxes. If more than 100 - exclusively for working with a phase inverter or in bandpasses. If the value is between 50 and 100, then you need to carefully look at other parameters - what type of acoustic design the speaker tends to. It is best to use special computer programs for this, which can graphically simulate the acoustic output of such a speaker in different acoustic design. True, you can’t do without other equally important parameters - Vas, Sd, Cms and L.

This is the so-called effective radiating surface of the diffuser. For the lowest frequencies (in the piston action zone), it coincides with the design one and is equal to:

The radius R in this case will be half the distance from the middle of the width of the rubber suspension on one side to the middle of the rubber suspension on the opposite side. This is due to the fact that half the width of the rubber suspension is also a radiating surface. Please note that the unit of this area is square meters. Accordingly, the radius must be substituted into it in meters.

This requires the results of one of the readings from the very first test. You will need the impedance (impedance) of the voice coil at a frequency of about 1000 Hz. Since the reactive component (XL) is separated from the active Re by an angle of 900, we can use the Pythagorean theorem:

![]()

Since Z (coil impedance at a certain frequency) and Re (coil DC resistance) are known, the formula translates to:

![]()

Having found reactance XL at frequency F, we can calculate the inductance itself using the formula:

Vas measurements

There are several ways to measure equivalent volume, but two are easier to use at home: the "Added Mass" method and the "Added Volume" method. The first of them requires several weights of a known weight from materials. You can use a set of weights from pharmacy scales or use old copper coins of 1,2,3 and 5 kopecks, since the weight of such a coin in grams corresponds to the face value. The second method requires an airtight box of known volume with an appropriate speaker hole.

Finding Vas by the method of additional mass

First you need to evenly load the cone with weights and again measure its resonant frequency, writing it as F "s. It should be lower than Fs. It is better if the new resonant frequency is 30% -50% less. The weight of the weights is taken approximately 10 grams per each inch of cone diameter. That is, for a 12" head, a weight of about 120 grams is needed.

The complexity of measuring the electrical and acoustic parameters of the speakers often pushes for the abandonment of this procedure, and subsequently the process of creating speakers takes place with a focus on simple calculation formulas that take into account only the electrical parameters of the speakers, and even then they are ideal. I think it makes no sense once again to delve into the stories that the result in this case does not even come close to meeting expectations. I will not dissemble, the measurement process is complicated, it requires some special equipment and, which is very important, skills in working with measurement programs. It is not enough just to measure, you need to do it as objectively as possible, and the only limitation in measurements should be the error of the measuring equipment.

Next, I will try to tell in detail about the measurement technique in the Arta Software package. I fell in love with this program for its convenience and ease of use, the possibility of a comprehensive analysis of the measurement results. The latest version of the program is available at developer site . At the moment it is version 1.6.1. There you can also download the original manuals for working with the components of the package, however, in English. These guides are included in the help system of the program. You can call it through the menu Help-User Manual.

You will need some equipment to take measurements. Below is what I use:

- Dell Inspiron 1720 laptop with Windows XP Professional x86 and Arta Software installed.

- Sound card E-MU 0404 USB.

- Amplifier Denon PMA-500AE. It is suitable because it has a bypass function for tone correction, loudness and balance - Source Direct.

- Voltmeter V7-38.

- Shop resistance R33.

- Measuring microphone Nady CM 100.

- Microphone stand. In its role is the stand from the camera, which has the functions of tilt, rotation and height adjustment.

- “Reference” resistor (Rref) needed for impedance measurements. I use PEV-10 with a nominal value of 10 ohms. The measured resistance is 9.85 ohms.

- Two cables with dividers that protect the input of the sound card from dangerous voltages. The dividers are soldered inside the TRS jack.

- An XLR microphone cable and several cables for connecting the I/O of the sound card and connecting it to the amplifier.

To measure the impedance, you need to connect the equipment according to Figure 12.

Figure 12

The impedance is measured by the voltage drop across the resistor Rref. Arta Software developers recommend using Rref value of 27 ohms. I use a smaller value - 10 ohms (measured resistance is 9.85 ohms), which allows me to set a lower voltage amplitude at the amplifier output when measuring. The actual resistance of the resistor Rref must be measured with a minimum error. This affects the impedance measurement error and, as a consequence, the error in calculating the Thiel-Small parameters.

In Arta Software, it is possible to measure the impedance of both low- and mid-frequency speakers, as well as high-frequency ones. For the latter, a separate technique is used - measurement on a step sinusoidal signal in a given frequency range. It is impossible to measure the impedance of high-frequency speakers on periodic noise, they may be damaged.

So let's start Limp. To do this, in the Windows Start menu, select All programs – Arta Software – Limp . The program window is shown below (Figure 13).

Figure 13

Here, as well as in Arta, I change the color scheme to a more pleasing to the eye. Changing the color of the workspace is done using the menu command Edit – B/W background color, other colors are changed via the menu Edit - Colors and grid style . Additionally, I turn off the selection of lines through the menu Edit – Use thick pen.

Program setup starts from the menu Setup-Audio devices(Figure 14). Here, in the Wave Input Device and Wave Output Device fields, you must specify the sound card you are using.

Figure 14

Next menu – Setup-Measurement(Figure 15).

figure 15

In the Reference Channel field, specify the channel that serves as the reference. If the connection of the measurement circuit is made in accordance with the image Figure 12, then the reference channel is right (Right). In the Reference Resistor field, specify the measured value of the resistor Rref. The High cut-off and Low cut-off fields indicate the frequency range of the impedance displayed on the screen. Not the frequency range itself, the display of which is changed through the menu Setup-Graph, but precisely the frequency range of the impedance curve. The above is true for measurements on periodic noise. For measurements on a stepping sinusoidal signal, these fields are responsible for the measurement range. In the Frequency increment field, the step for measurements on a step sinusoidal signal is set. I recommend setting it to 1/48th of an octave, thus getting a smaller step and a more accurate impedance measurement. Fields Min. integration time (ms) , Transient time (ms) and Intra burst pause (ms) determine the integration time, the step duration of the sine wave, and the pause between steps, respectively. If the computer you are measuring is not fast enough, double the values in these fields. The FFT size field sets the FFT block size. Setting a larger value improves the frequency resolution but increases the measurement time. The remaining fields set the averaging of the measurement results. These fields can be useful when making impedance measurements with additional mass, if the latter cannot be attached to the speaker cone. Small fluctuations in the added mass make the displayed HFC appear rough. Averaging helps a little to get rid of this. Averaging works only for measurements on periodic noise.

Next, I describe an impedance measurement technique suitable for bass and midrange speakers. You cannot use this technique to measure tweeters. For them, the measurement technique will be described below.

Now you need to set the amplitude of the current through the voice coil of the measured speaker. Taking into account the nonlinearity of the parameters of the speakers at different current through the voice coil, it is desirable to use a current of at least 40-50 mA for measurements. To set the amplitude of the current, a resistor with a value close to the nominal resistance of the speaker is connected to the measurement terminals. I have a 4A28 broadband speaker as a test subject. Its nominal resistance is 12 ohms, which is how much I set on the resistance store. A voltmeter is connected in parallel with the test resistor. The current through the resistor is calculated using Ohm's law.

Connected, go to the menu - Setup-Generator(Figure 16).

Figure 16

In the Type field, the type of signal for measurements is set - periodic pink noise (Pink PN) or sine (Sine). In the Output level field, you can change the test signal level, which is convenient, for example, when evaluating the linearity of loudspeakers. In the Sine freq field. (Hz) sets the frequency of the generated sine wave. In the Pink cut-off (Hz) field – cutoff frequency of pink noise. I do not recommend using too low a value (for example, 20 Hz), because when measuring with additional mass, due to the increase in amplitude at low frequencies, the weights on the cone can cause distortion of the IFC.

First, select Sine in the Type field. In the Sine freq field. (Hz) set the frequency to 315 Hz. If a wide range voltmeter is not available, use a lower value, such as 100 or 50 Hz. In the Output level field, set the value to 0 dB. Press the Test button. We set the required current through the resistor. I set the output voltage of the amplifier to 0.6063 v, which corresponds to a current of about 50 mA through a 12 ohm load. We stop the generation by pressing the Test button again. Disconnect the resistor from the test terminals and press the Test button again. The Generator Setup window displays the input signal levels of the left and right channels. By adjusting the sensitivity, we set the level in the range of -20 ... -10 dB. It should be set identical for both channels. After installation, we stop the generation by pressing the Test button. In the Type field, select Pink PN, thereby setting the periodic pink noise for the test. We press OK.

On the menu Setup-Graph(Figure 17) You can change the displayed frequency range and impedance value range on the screen. The View Phase checkbox is responsible for displaying the phase of the impedance. This menu can also be called by right-clicking on the chart.

Figure 17

Go to the menu Record-Calibrate(Figure 18).

Figure 18

Here is the calibration procedure. Press the Generate button. The indicator will show the level of input signals. The level should be the same as it was set in the menu Setup-Generator(Figure 16). We stop the generation by pressing the Generate button again. In the field Number of averages (averaging) set the value 3 ... 5. Press the Calibrate button. Upon completion of the calibration, on the right, in the Status window, information about the number of test signal samples, sampling frequency and voltage amplitude difference between the channels will be displayed (Figure 19). If this difference exceeds 2 dB, the program will issue a warning. A good result should be recognized as a difference value of less than 0.2 dB. We press OK.

figure 19

Everything is ready for measurements. I will make a small digression and give a table with the values of the relative error in measuring the resistance (Figure 20). The relative error is calculated by the formula ((Rm-Rs)/Rs)*100, where Rs is the resistance value set on the resistance box, Rm is the resistance value measured by Limp.

figure 20

We measure the DC resistance (Re) of the voice coil of the speaker with an ohmmeter and connect the speaker to the terminals for the test. It is undesirable to place the speaker on the floor. A small stand with a platform smaller than the diameter of the speaker magnet works best. If it is possible to fix the speaker on weight, this will be a very good solution. Be careful with speakers that have a hole in the core. Such dynamics can only be measured by weight.

In Limp, starting and stopping the measurement process is done either through the menu Record–Start and Record–Stop, or using the buttons on the taskbar. The Start button is indicated by a red triangle, the Stop button by a red circle. We start the measurement process. After displaying the impedance and phase on the screen (Figure 21), stop the measurement.

figure 21

The measurement result can be saved with *.lim extension ( File - Save As...), or export to *.txt, *.zma, *.csv format ( File-Export as...). If you are exporting to *.csv, the decimal separator (dot or comma) can be selected via the menu Setup-CSV format.

After measuring the impedance, an incomplete list of Thiel-Small parameters can be calculated. For it's on the menu Analyze must choose either Loudspeaker parameters – Added mass method , or Loudspeaker parameters – Closed box method . The first menu item is intended for calculating the Thiel-Small parameters by the method of additional mass, the second - using a measuring box. In this case there is no difference, but I use the extra mass menu out of habit (Figure 22).

Figure 22

In the window that opens, in the Voice coil Resistance (ohms) field, specify the DC resistance of the voice coil of the speaker and press the Calculate TSP button. To calculate all the Thiel-Small parameters, one more impedance measurement must be carried out - with an additional mass. Close the current window. On the menu overlay choose Set as overlay. The impedance curve will be fixed by the program and will change color on the graph.

As an additional mass, I use coins from the times of the USSR. Their face value (1, 2, 3 and 5 kopecks) corresponds to the weight in grams. The optimal amount of additional mass is such that the frequency of the main resonance of the moving system is reduced by 20-50%. It is impossible to name the exact amount of this mass, therefore, to begin with, you should choose a small value - 10-15 grams. In the future, it will be possible to add (or subtract) and measure again.

We place the mass on the speaker cone, carry out the measurement (Figure 23).

Figure 23

Let's go to the menu. In the Voice coil Resistance (ohms) field, specify resistance to direct current , in the field Membrane diameter (cm) - the diameter of the radiating surface in centimeters (measured between the suspension centers ), in the field Added mass (g) - the additional mass in grams , after which we press the button Calculate TSP (Figure 24).

Figure 24

Data can be copied to the clipboard (Copy to Clipboard ), or exported to a *.csv file (Export in .CSV file ).

To measure the impedance of high-frequency speakers, you need to make some changes to the program settings. Also, as before starting measurements of low- and mid-frequency speakers, a resistor with a nominal resistance equal to the nominal resistance of the speaker is connected to the test terminals. A voltmeter is connected in parallel with the resistor. Using the menu - Setup-Generator(Figure 16) we set the current through the resistor, similar to the method described above with the only difference - the current through the resistor must be set within 10 mA . This is a safe current value for gentle tweeters. Upon completion of the current setting, we adjust the sensitivity as described earlier. At the end of the setup procedure, set the Generator Setup menu in the Type field to Sine and click OK.

Go to the menu – Setup-Measurement(Figure 15). In field Low cut-off sets the lower limit of the measurement frequency range. For dome tweeters with a low (600-700 Hz) resonant frequency, a value of 200 Hz can be used. Install and click OK.

On the menu Record-Calibrate(Figure 18) perform the calibration procedure described above.

Caution does not hurt, so first, instead of the speaker, we connect a resistor to the measurement terminals and start the measurement process. After making sure that the process begins to proceed in accordance with the specified settings, we stop the measurement. Now we connect the measured speaker to the test terminals and start the measurement process again. At the end of the measurements, the generator will stop automatically. The very process of measuring on a stepping sinusoidal signal is a rather lengthy procedure, be patient.

Figure 25

If you are interested in the Thiel-Small parameters, you can calculate them through the menuAnalyze – Loudspeaker parameters – Added mass method . It is enough to specify the DC resistance of the voice coil and press the Calculate TSP button (Figure 26).

Figure 26

Special thanks to Sirvutis Alexey ( Lexus) for the information provided.

(To help beginner bassists )

Chapter A - Measurements

I’ll make a reservation right away that the most convenient way to measure the parameters of woofers is set out in the method. I suggest that the owners of the program use this method (I myself have not tested it, but I think there are no glitches there). For those who do not have this program or do not have enough measuring equipment, I will describe the method that I scooped up from the RADIO magazines of past years. I used this method, and with a certain degree of accuracy and perseverance, with its help, you can get quite accurate (more precisely than in the reference book or in the user manual) parameters.

So, let's begin:

1) Let's assemble the circuit.

Where in the diagram is the tested speaker, I think it's clear. The remaining elements of the scheme require a detailed explanation.

Generator - either an audio frequency generator capable of delivering a voltage of 10-20 V, or an oscillator-amplifier combination that meets the same requirement.

1000 ohm - 1000 ohm resistor that stabilizes the current through the speaker. The resistor value can be taken less, but this will reduce the accuracy of Qts calculation. (True, when using a resistor of only 200 ohms, the measurement error is unlikely to exceed 10%, but, as they say, careful ...).

a, c, c - points for connecting a voltmeter.

The voltmeter itself is not indicated in the figure, but it must be: - firstly, alternating current; - secondly, to be able to measure voltages of the order of 100 mV. If the voltmeter does not have such a measurement limit, it can be connected through an amplifier. And since modern amplifiers are usually "stereo" and more, there are no particular problems with this.

The scheme is assembled.

2) We place the speaker away from walls, ceiling and floor (it is often recommended to hang it).

3) Connect the voltmeter to the points a and with, and set the voltage to 10-20 V at a frequency of 500-1000 Hz.

4) We connect the voltmeter to the points in and with, and by changing the frequency of the generator we find the frequency at which the voltmeter readings are maximum, see the figure below in the text. This is Fs. We write down the Fs and Us readings of the voltmeter.

5) By changing the frequency up relative to Fs, we find frequencies at which the voltmeter readings are constant and much less than Us (with a further increase in frequency, the voltage will again begin to increase, in proportion to the increase in the speaker impedance). Let's write down this value, Um.

The graph of the speaker impedance in free space and in a closed box looks something like this.

6) We find according to the graph (if we built it) or measure the cutoff frequencies F1 and F2 according to the level U12=(Us*Um)^0.5;

7) Calculate the acoustic Q factor Qa=(Us/Um)^0.5*Fs/(F2-F1), and

8) Electrical quality factor Qe=Qa*Um/(Us-Um);

9) And, finally, the total quality factor Qts=Qa*Qe/(Qa+Qe).

To recognize Vas, we need a box (a good sealed box, by no means made of cardboard, but with thick walls) with a round hole the same size as the diameter of the speaker cone. The volume of the box, V, is better to choose closer to the one in which we are then going to listen to this speaker.

10) We install the speaker in the box and seal all the cracks;

11) We carry out all measurements and calculations according to points 1)-6) and obtain the values Fs "(actually it is Fc) and Qts" (Qtc);

12) Calculate Vas=((Fs"/Fs)^2-1)*V;

13) Calculate Qtc=Qts*(1+Vas/V)^0.5, if the measured Qts"=Qtc, well, or almost equal, then everything is done correctly, and you can proceed to the design of the acoustic system.

Chapter B - Setting the PHI

The proposed tuning technique is also written off from the Literature, but it is simple enough to become the property of the curious masses. The only caveat (I came up with it myself) is that this technique allows you to easily tune the FI, made on the basis of speakers with a quality factor Qts = 0.3 ... 0.5. For other FIs, you will have to additionally use natural ingenuity. So.

The method is based on the dependence that exists between the parameters FI and CL (closed box). If the tunnel hole is closed in a FI with a smooth frequency response (by spl), then the total quality factor of the system, Qtc, will be equal to 0.6, and the resonant frequency, Fc, will be related to the FI tuning frequency by the dependence: Fb=0.61…0.65*Fc. If we assume an error in determining the FI tuning frequency of 5%, then the ratio Fb/Fc for real structures can be taken equal to 0.63.

Customization:

14) We close the tunnel opening hermetically, and assemble the circuit for measuring Fc (see chapter A).

15) We select the amount of sound-absorbing material and achieve the minimum value of Fc;

16) We fix the material inside the box and measure Fc;

17) Calculate Fb=0.63*Fc;

18) Calculate the length of the tunnel: Lv=31*10^3*S/(Fb^2*V)-1.7*(S/PI)^0.5, where S is the area of the FI port opening in sq.cm, V - the volume of the box in liters;

19) We make a tunnel, insert it inside the box (exactly inside, if it is supposed to be inside in the finished structure) and measure Fb".

It should turn out something like:

20) The resulting value of Fb" is substituted into the formula 18) and the corrected value of V" is calculated;

21) We substitute V "in f-lu 18) and calculate Lv" for the calculated value of Fb (who forgot, this happened in paragraph 17);

22) We shorten (it is impossible to lengthen it, so it is better to take measures in advance) the tunnel and measure again;

23) According to the method for determining Qtc (Chapter A), we determine the quality factor of the system and, if it is less than 1, we calm down. If it is larger, then probably something was done wrong somewhere, but it's too late to redo it. Listen, if it really mumbles (which is not at all necessary), we will take action.

Possible measures:

24) Dampen the FI tunnel with a partially acoustically transparent material. In other words, close the tunnel with synthetic winterizer, cotton wool, carpet, etc.;

25) Dampen the speaker itself by sticking the materials listed above on the windows of the diffuser holder (but not all at once).

These measures will reduce the overall quality factor of the system, Qtc.

Literature:

Saltykov O., Calculation of loudspeaker characteristics, Radio 1981

Zhbanov V., Setting up a phase inverter, Radio 8/1986

Aldoshina I. Where basses live, AM 2/1999

Frunze, On improving the sound quality of speakers, Radio 9/1992

) dynamics. The methods described below are sufficient for the beginner car audio tinker and allow T/S measurements with a minimum of equipment.

To measure these parameters using the method described below, you will need the following items:

- One (1) amplifier

- One (1) tone generator

- One (1) digital multimeter

- One (1) 5 watt resistor (approximately 4 or 8 ohms)

- Two (2) pairs of alligator wires

Preferably, the multimeter should be capable of measuring frequency as well as voltage, resistance, and current. The amplifier must be able to reproduce from 20 Hz to 200 Hz without the possibility of change in output power and it must be insensitive to loads over 4 ohms. The frequency tone generator must also be able to reproduce a signal whose voltage does not change as the frequency is adjusted.

Thiel-Small parameter measurement method

- Measure the resistance (Re) of the speaker directly.

- Measure the resistance (Rs) across the resistor.

- Connect the tone generator to the amplifier's input terminals.

- Connect a multimeter to the amplifier's acoustic output terminals.

- Set the tone generator to about 100 Hz.

- Set the amplifier output to Vs, where Vs~0.5 to 1.0 Volts. You may need to experiment with different voltages, depending on the accuracy of your meter.

- Calculate Is where Is = Vs/(Re+Rs)

- Connect the following circuit (using alligator clips when necessary):

- Attach one leg of the resistor to the positive terminal on the amplifier

- Attach the second leg of the resistor to the positive terminal on the speaker

- Connect the negative terminal of the speaker to the negative terminal on the amplifier

- Attach multimeter leads to each side of the resistor

- Adjust the frequency until the voltage across the resistor reaches the minimum level.

- We fix the frequency value, Fs

- We fix the voltage across the resistor, Vm

- Calculate the current, Im = Vm/Rs, flowing through the circuit

- We calculate the impedance of the speaker at the resonant frequency, РRm = (Vs-Vm) / Im

- We get -3dB current, Ir = (Im*Is)^0.5

- Calculate r0=Is/Im

- Calculate -3dB voltage, Vr = Ir*Rs

- We get the frequencies Fl and Fh, for which the voltage through the resistor is Vr

- Make sure (Fl*Fh)^0.5 = Fs

- If everything fits, then Qes, Qms and Qts can be calculated as follows:

- Qms = Fs*(r0^0.5)/(Fh-Fl)

- Qes = (Qms/(r0-1))*(Re/(Rs+Re))

- Qts = Qms*Qes/(Qms+Qes)

You can use the following table to perform calculations automatically:

Vas measurement (speaker equivalent volume)

To measure Vas, one should use a good, sturdy enclosure of known volume that matches the speaker's nominal size. Install the speaker with the cone outward and provide easy access to the contacts. Calculate the volume of the case, taking into account the loss from the speaker installed inside. Measure the resonant frequency in this position.

Vas = Vb((Fb/Fs)^2 - 1)

VB is the volume of the speaker cone plus the volume of the box

Fb - resonant frequency of the speaker in the box